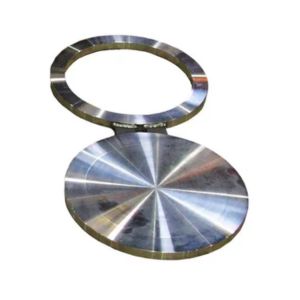

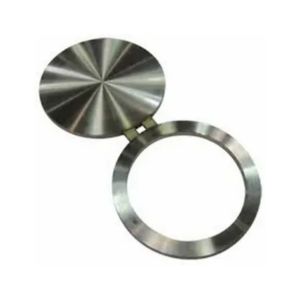

Harsh Flanges is a prominent manufacturer and supplier company located in Mumbai, India, catering to the high-grade Titanium Spectacle Flanges. Being a firm believer in delivering excellence, we provide a complete lineup of titanium flanges, such as Grade 2 (UNS R50400) and Grade 5 (UNS R56400), addressing various industrial applications. Our products are designed to international standards in order to ensure maximum performance and reliability. As reliable suppliers, we cater to customers from different industries with customized solutions to address individual needs. Harsh Flanges is a quality and innovation hallmark of the titanium flange business.

Titanium Spectacle Flanges are mostly made of titanium alloys, where Grade 2 (UNS R50400) has a content of at least 99.2% titanium and Grade 5 (UNS R56400) has 90% titanium, with some aluminum (6%) and vanadium (4%). Small percentages of carbon, iron, hydrogen, nitrogen, and oxygen might be present in Grade 2 flanges. These compositions provide superior corrosion resistance, high strength-to-weight, and superior weldability, which render them acceptable for challenging applications in several industries. Grade 2 flanges have a tensile strength of 344 MPa and yield strength of 275 MPa, and Grade 5 flanges offer a tensile strength of 950 MPa and yield strength of 880 MPa. These characteristics guarantee durability and reliability under high pressure and temperature.

| Trade name | Titanium Spectacle Flanges |

| Titanium Spectacle Flanges Standard | ASTM B381 / ASME SB381 ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges |

| Titanium Spectacle Flanges Dimensions | B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Titanium Spectacle Flanges Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000) |

| Titanium Spectacle Flanges Class/Pressure |

|

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| SB 381 Grade 2 Titanium Spectacle Blind / Blind and Spacers Flanges Marking | All Flanges are marked as follows: Grade, Standard, Thickness, Heat No. (Or according to the customer’s request.) |

| Delivery Time | 7-15 working days as usual, It will based on the detailed order quantity. |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Titanium Spectacle Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Titanium Spectacle Flanges are widely used in various industries because of their outstanding characteristics. In aerospace, they are used in fuel systems and jet engines, where high strength and corrosion resistance are necessary. The marine industry uses these flanges for ship construction and offshore platforms, taking advantage of seawater corrosion resistance. They are employed in piping systems that convey aggressive chemicals in chemical processing. Titanium flanges are used in the power generation sectors, such as geothermal and nuclear, to carry parts that are subjected to harsh temperatures and pressures. Being lightweight and durable, they are also ideal for application in medical fields, where fatigue and wear are lessened in implants.

| Element | Titanium | Nitrogen | Carbon | Hydrogen | Iron | Oxygen | Residuals (each) | Residuals (total) |

| % | Balance | 0.03 max | 0.08 max | 0.015 max | 0.30 max | 0.25 max | 0.1 max | 0.4 max |

| 0.2% Proof Stress | Tensile Strength | Elongation | |

| MPa | MPa | % | |

| Annealed | 275-450 | 345 | 20 |

| STANDARD | UNS | WERKSTOFF NR. |

| Titanium Gr 2 | R50400 | 3.7035 |

| Titanium Gr 5 | R56400 | 3.7165 |

Yes, we offer custom sizes for Titanium Spectacle Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved