Harsh Flanges stands out as a top-notch manufacturer and supplier of Titanium Grade 5 Flanges, proudly based in Mumbai, India. We’re all about delivering high-quality products that meet the toughest industry standards. Our Titanium Grade 5 Flanges are renowned for their impressive strength-to-weight ratio and resistance to corrosion, making them perfect for critical and high-performance applications. We employ cutting-edge manufacturing techniques and rigorous quality controls to guarantee precision, reliability, and durability. Whether it’s aerospace, marine, chemical processing, or medical fields, Harsh Flanges is dedicated to providing trustworthy solutions that excel even in extreme conditions.

When it comes to composition, Titanium Grade 5 Flanges are primarily made up of titanium (90%), along with 6% aluminum and 4% vanadium, which gives them outstanding strength and corrosion resistance. They boast high tensile strength (around 895 MPa), yield strength of about 828 MPa, and a good elongation rate (10–15%). With a melting point of roughly 1,660°C and remarkable fatigue resistance, these flanges perform exceptionally well under high temperatures and pressure. Their lightweight design, paired with excellent mechanical properties, makes them ideal for demanding environments where strength and performance are non-negotiable.

| Standards | GOST Flange, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN |

|---|---|

| Pressure Rating ANSI | Class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600, |

| Pressure Calculation in DIN | 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6 |

| JIS | 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K, |

| UNI | 10Bar 16Bar 6Bar 25Bar 40Bar |

| EN | 6Bar 25Bar 40Bar 10Bar 16Bar |

| Most common Types | Threaded / Screwed / Forged / Plate |

| Production technique |

|

| Shapes and Types we produce | Large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF),Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF) |

| Test | Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

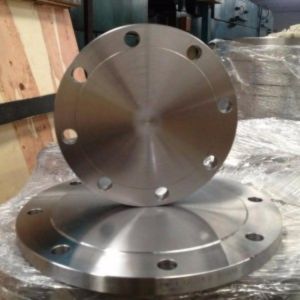

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Titanium Gr 5 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

You’ll find Titanium Grade 5 Flanges widely used across various sectors, including aerospace, marine, chemical processing, oil and gas, desalination, and medical industries. Their superior corrosion resistance makes them a go-to choice for saltwater, reactive chemical environments, and high-temperature systems. In the aerospace and automotive industries, they help cut down on weight while still maintaining strength. In the medical realm, they’re utilized for biocompatible applications like implants and surgical tools. These flanges are also popular in heat exchangers, reactors, and pressure vessels, where performance, longevity, and reliability are crucial in corrosive or high-stress operating conditions.

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr. 5 | 3.7165 | N56400 |

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade5 | 90 min | – | 0.25 max | – | – | 0.2 max | 6 min | 4 min |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Yes, we offer custom sizes for Titanium Gr 5 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved