Harsh Flanges is a well-respected manufacturer and supplier of Titanium Grade 2 Flanges, located in Mumbai, India. We provide high-performance flange solutions tailored for critical industrial applications. Renowned for our commitment to quality, precision, and reliability, Harsh Flanges specializes in lightweight and corrosion-resistant Titanium Gr 2 flanges that meet global quality standards. With state-of-the-art production facilities and a dedication to excellence, we serve a variety of sectors, including chemical processing, marine, aerospace, and medical industries. Our Titanium Grade 2 Flanges are designed to deliver long-lasting performance in challenging and corrosive environments, ensuring optimal safety, strength, and longevity.

Titanium Grade 2 Flanges are made from commercially pure titanium (at least 98.9%) with trace amounts of iron, oxygen, carbon, nitrogen, and hydrogen. These flanges are known for their outstanding corrosion resistance, especially in oxidizing and mildly reducing environments. They boast a tensile strength of around 344 MPa, a yield strength of about 275 MPa, and an elongation of roughly 20%. Titanium Gr 2 also provides good ductility, weldability, and moderate strength, making it ideal for both low and moderate-pressure applications, particularly where high corrosion resistance and biocompatibility are crucial.

| Standards | GOST Flange, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN |

|---|---|

| Pressure Rating ANSI | Class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600, |

| Pressure Calculation in DIN | 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6 |

| JIS | 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K, |

| UNI | 10Bar 16Bar 6Bar 25Bar 40Bar |

| EN | 6Bar 25Bar 40Bar 10Bar 16Bar |

| Most common Types | Threaded / Screwed / Forged / Plate |

| Production technique |

|

| Shapes and Types we produce | Large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF),Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF) |

| Test | Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

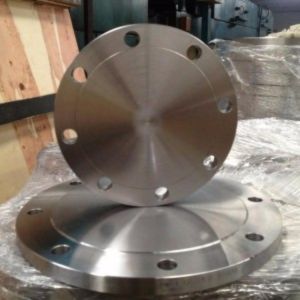

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Titanium Gr 2 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

You’ll find Titanium Gr 2 Flanges widely utilized across various industries, including chemical processing, marine, desalination, medical, aerospace, and power generation. Their exceptional resistance to seawater and corrosive chemicals makes them perfect for heat exchangers, piping systems, condensers, and pressure vessels in harsh environments. In the medical field, they are favored for surgical instruments and implants due to their biocompatibility. In aerospace, they help reduce weight without compromising strength. These flanges are also suitable for the oil and gas, pulp and paper, and electroplating industries, where long-term durability is essential.

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | – | – |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr. 2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr. 2 | 3.7035 | R50400 |

Yes, we offer custom sizes for Titanium Gr 2 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved