Harsh Flanges is a reputable manufacturer and supplier of Low Temperature Carbon Steel LF1 Flanges, proudly based in Mumbai, India. They specialize in providing precision-engineered solutions for industries that need dependable performance in chilly environments. Renowned for their commitment to quality, Harsh Flanges ensures that their products meet rigorous international standards by utilizing top-notch materials and cutting-edge manufacturing techniques to create durable, corrosion-resistant LF1 flanges. These flanges are perfect for applications that involve low-temperature service, particularly in cryogenic and pressure systems. Harsh Flanges caters to a variety of sectors, including petrochemical, oil and gas, and power, offering cost-effective, customized, and timely solutions that are tailored to meet customer needs.

Low Temperature Carbon Steel LF1 Flanges are primarily made from carbon steel, with carefully controlled levels of carbon, manganese, phosphorus, sulfur, and silicon to boost toughness in sub-zero temperatures. Typically, these flanges showcase a tensile strength of 485 MPa and a yield strength of 250 MPa, along with impressive impact resistance even at temperatures as low as -46°C. Their mechanical properties guarantee outstanding performance in low-temperature service environments, featuring excellent weldability, toughness, and structural integrity, making them ideal for pressure systems that operate under extreme conditions.

|

Specifications |

ASTM A350 LF2 / ASME SA350 |

|

Dimensions |

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

|

Standard |

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

|

Size |

1/2″ to 48″ |

|

Material |

ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2 |

|

Class / Pressure |

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

|

Flange Face Type |

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

|

Element |

Weight % |

|

Carbon |

0.30 max |

|

Silicon |

0.15 – 0.30 |

|

Manganese |

0.6 – 1.35 |

|

Phosphorus |

0.35 max |

|

Sulphur |

0.040 max |

|

Molybdenum |

0.12 max |

|

Copper |

0.40 max |

|

Chromium |

0.30 max |

|

Nickel |

0.40 max |

|

Vanadium |

0.08 max |

|

Niobium |

0.02 max |

|

Property |

Values |

|

Ultimate Tensile Strength |

485 – 655 N/mm2 |

|

0.2% Yield Strength |

250 N/mm2 min |

|

Elongation |

22% min |

|

Reduction of Area |

30% min |

|

Charpy Impact Toughness |

20 average / 16 min J at -46o C |

|

Hardness |

197 HB |

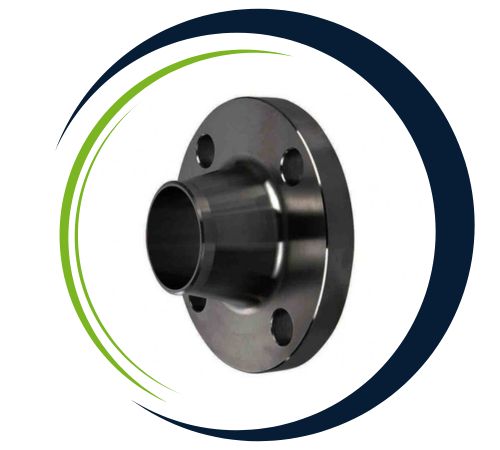

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Low Temperature Carbon Steel LF2 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

These LF1 flanges are widely utilized in industries where systems function in sub-zero or cryogenic conditions, such as natural gas processing, LNG plants, petrochemical facilities, and cold storage infrastructure. They are particularly suited for connecting pipes, valves, and pressure vessels where strength and ductility are essential at low temperatures. With their resistance to brittleness and remarkable mechanical stability, these flanges ensure safe and leak-proof connections in demanding environments. LF1 flanges deliver reliable performance in pipelines and equipment that handle cold fluids, enhancing both system longevity and operational safety across various low-temperature industrial applications.

Yes, we offer custom sizes for Low Temperature Carbon Steel LF2 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved