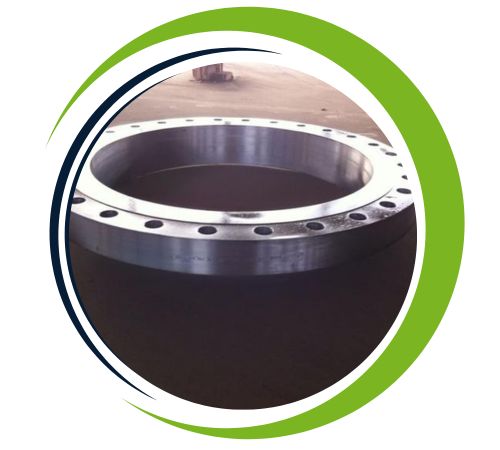

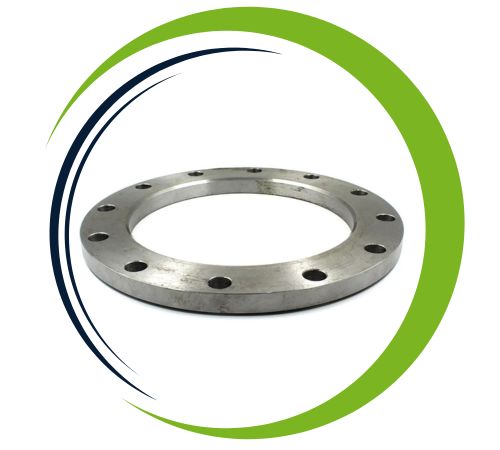

Based in Mumbai, India, Harsh Flanges is a reputable producer and supplier of large diameter flanges. Harsh Flanges is well known for providing precisely engineered flange solutions that are suited to a variety of industrial needs, and it has a significant presence in both domestic and foreign markets. Because of their ability to tolerate high temperatures and pressures, our large diameter flanges are appropriate for demanding applications across a range of industries. These flanges, which are made with premium materials and cutting-edge technology, are renowned for their exceptional performance, dimensional accuracy, and longevity. Harsh Flanges is dedicated to quality, guaranteeing timely delivery and compliance with international standards.

Carbon steel, stainless steel (304, 316), duplex steel, and alloy steel are common materials used to make large diameter flanges. To improve strength and resistance to corrosion, the chemical composition contains necessary elements such as manganese, nickel, molybdenum, and chromium. Tensile strength of 450–620 MPa, yield strength of 170–250 MPa, and elongation above 20% are typical mechanical properties, though they vary depending on the grade of material. In large-scale pipeline systems and pressure vessels, these flanges are made to withstand high-stress situations, guaranteeing structural integrity and long-term dependability.

| Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

|---|---|

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating ANSI | Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF) |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Material | Inconel Large Diameter Flange, Hastelloy Large Diameter Flange, AISI 4130 Large Diameter Flange, Incoloy Big Diameter Flange, Nickel Alloy Large Diameter Flange, Titanium Big Diameter Flange, Super Duplex Big Diameter Flange, Brass Large Diameter Flange, Alloy 20 Large Diameter Flange, Duplex Steel Large Diameter Flange, Monel Large Diameter Flange, SMO 254 Big Diameter Flange, Stainless Steel Big Diameter Flange, Copper Nickel Large Diameter Flange. |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Large Diameter Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

In industries where connecting large pipelines or high-volume fluid systems is essential, large diameter flanges are essential. They are frequently utilised in power generation, petrochemical facilities, water treatment facilities, oil and gas pipelines, marine applications, and infrastructure projects. In systems that move liquids, gases, or steam under high pressure, these flanges offer strong sealing and support. They are perfect for critical systems because of their large size, which makes inspection, cleaning, and maintenance simple. Large diameter flanges are particularly useful in specially designed systems where safe and effective operation depends on accuracy, robustness, and resistance to harsh environmental conditions.

| NPS | Pipe Diameter | Flange Inside Daimeter | Number of holes | Flange Daimeter | Thickness of Flange | Daimeter of Bolt Circle | Daimeter of Bolt Holes | Approx.Weight in kg | |

| DN | ISO | DIN | D5 | BN | D | b | K | d2 | KG/PCS |

| 10 | – | 14 | 14.5 | 4 | 90 | 16 | 60 | 14 | 0.7 |

| 17.2 | – | 17.7 | 4 | 90 | 16 | 60 | 14 | 0.69 | |

| 15 | – | 20 | 21 | 4 | 95 | 16 | 65 | 14 | 0.77 |

| 21.3 | – | 22 | 4 | 95 | 16 | 65 | 14 | 0.77 | |

| 20 | – | 25 | 26 | 4 | 105 | 18 | 75 | 14 | 1.06 |

| 26.9 | – | 27.6 | 4 | 105 | 18 | 75 | 14 | 1.05 | |

| 25 | – | 30 | 31 | 4 | 115 | 18 | 85 | 14 | 1.27 |

| 33.7 | – | 34.4 | 4 | 115 | 18 | 85 | 14 | 1.25 | |

| 32 | – | 38 | 39 | 4 | 140 | 18 | 100 | 18 | 1.86 |

| 42.4 | – | 43.1 | 4 | 140 | 18 | 100 | 18 | 1.83 | |

| 40 | – | 44.5 | 45.5 | 4 | 150 | 18 | 110 | 18 | 2.12 |

| 48.3 | – | 49 | 4 | 150 | 18 | 110 | 18 | 2.09 | |

| 50 | – | 57 | 58.1 | 4 | 165 | 20 | 125 | 18 | 2.78 |

| 60.3 | – | 61.1 | 4 | 165 | 20 | 125 | 18 | 2.74 | |

| 65 | 76.1 | – | 77.1 | 8 | 185 | 22 | 145 | 18 | 3.48 |

| 80 | 88.9 | – | 90.3 | 8 | 200 | 24 | 160 | 18 | 4.33 |

| 100 | – | 108 | 109.6 | 8 | 235 | 24 | 190 | 22 | 5.82 |

| 114.3 | – | 115.9 | 8 | 235 | 24 | 190 | 22 | 5.61 | |

| 125 | – | 133 | 134.8 | 8 | 270 | 26 | 220 | 26 | 7.91 |

| 139.7 | – | 141.6 | 8 | 270 | 26 | 220 | 26 | 7.6 | |

| 150 | – | 159 | 161.1 | 8 | 300 | 28 | 250 | 26 | 10.12 |

| 168.3 | – | 170.5 | 8 | 300 | 28 | 250 | 26 | 9.58 | |

| 175 | 193.7 | – | 196.1 | 12 | 350 | 32 | 295 | 30 | 14.45 |

| 200 | 219.1 | – | 221.8 | 12 | 375 | 34 | 320 | 30 | 16.9 |

| 250 | – | 267 | 270.2 | 12 | 450 | 38 | 385 | 33 | 27.28 |

| 273 | – | 276.2 | 12 | 450 | 38 | 385 | 33 | 26.51 | |

| 300 | 323.9 | – | 327.6 | 16 | 515 | 42 | 450 | 33 | 36.38 |

| 350 | 355.6 | – | 359.7 | 16 | 580 | 46 | 510 | 36 | 52.83 |

| – | 368 | 372.2 | 16 | 580 | 46 | 510 | 36 | 50.24 | |

| 400 | 406.4 | – | 411 | 16 | 660 | 50 | 585 | 39 | 74.71 |

| – | 419 | 423.7 | 16 | 660 | 50 | 585 | 39 | 71.44 | |

| 500 | 508 | – | 513.6 | 20 | 755 | 52 | 670 | 42 | 86.87 |

| 600 | 610 | – | 616.5 | 20 | 890 | 54 | 795 | 48 | 121.84 |

| 700 | 711 | – | 716 | 24 | 995 | 58 | 900 | 48 | 150.93 |

| 800 | 813 | – | 818 | 24 | 1140 | 64 | 1030 | 56 | 219.08 |

| 900 | 914 | – | 920 | 28 | 1250 | 70 | 1140 | 56 | 271.16 |

| 1000 | 1016 | – | 1022 | 28 | 1360 | 78 | 1250 | 56 | 344.95 |

| Temperature (°C) | Class | ||||||

|---|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 | |

| -29 – 38 | 19.8 | 51.7 | 68.9 | 103.4 | 155 | 259 | 431 |

| 50 | 19.5 | 51.7 | 68.9 | 103.4 | 155 | 259 | 431 |

| 100 | 17.7 | 51.5 | 68.7 | 103.0 | 155 | 258 | 429 |

| 150 | 15.8 | 50.2 | 66.8 | 100.3 | 151 | 251 | 418 |

| 200 | 13.8 | 48.6 | 64.8 | 97.2 | 146 | 243 | 405 |

| 250 | 12.1 | 46.3 | 61.7 | 92.7 | 139 | 232 | 386 |

| 300 | 10.2 | 42.9 | 57.0 | 85.7 | 129 | 214 | 357 |

| 325 | 9.3 | 41.4 | 55.0 | 82.6 | 124 | 207 | 344 |

| 350 | 8.4 | 40.0 | 53.4 | 80.0 | 120 | 200 | 334 |

| 375 | 7.4 | 37.8 | 50.4 | 75.7 | 114 | 189 | 315 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104 | 174 | 290 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 144 | 240 |

| 450 | 4.6 | 23.0 | 30.7 | 46.0 | 69.0 | 115 | 192 |

| 475 | 3.7 | 17.1 | 22.8 | 34.2 | 51.3 | 85.4 | 142 |

| 500 | 2.8 | 11.6 | 15.4 | 23.2 | 34.7 | 57.9 | 96.5 |

| 538 | 1.4 | 5.9 | 7.9 | 11.8 | 17.7 | 29.5 | 49.2 |

Yes, we offer custom sizes for Large Diameter Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved