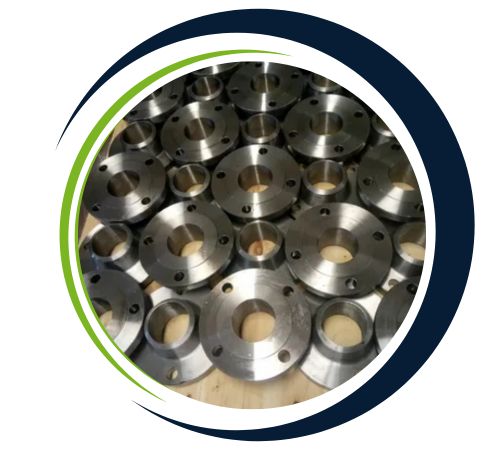

Harsh Flanges, based in Mumbai, India, stands out as a top manufacturer and supplier of Inconel Weld Neck Flanges, specifically crafted for demanding environments that involve high pressure, high temperatures, and corrosive conditions. Made from high-quality Inconel alloys like Inconel 600, 625, and 718, these flanges are built to provide outstanding mechanical strength, thermal stability, and resistance to corrosion. Our weld neck flanges meet international standards such as ASME, ANSI, and ASTM, guaranteeing top-notch quality and precise dimensions. Perfect for critical sectors like chemical processing, aerospace, offshore, and nuclear industries, Harsh Flanges delivers reliable, leak-proof Inconel weld neck flanges that fulfill stringent performance criteria.

Inconel Weld Neck Flanges are crafted from high-performance nickel-chromium alloys, including Inconel 600, 625, or 718. These alloys generally consist of 58–72% Nickel, 14–23% Chromium, and may also contain Molybdenum, Niobium, and Iron. Inconel is known for its impressive tensile strength (up to 1,030 MPa), yield strength (up to 760 MPa), and resistance to high temperatures. These flanges excel in resisting oxidation, carburization, and stress-corrosion cracking in extreme chemical and thermal settings. The long tapered hub design of weld neck flanges ensures structural integrity and effective stress distribution, making them perfect for high-stress and high-pressure pipeline systems.

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Inconel weldneck flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Standards: ASTM, ASME Flanges, ANSI Flanges, DIN Flanges, EN Flanges, BS Flanges etc.

Specification :ASTM B 564 / ASME SB 564

Size : ½” to 36″

Class : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Grade : Inconel (UNS N06600) Flanges, 2.4816

| Grade | Ni | Si | C | S | Mn | Cr | Fe | |

| Inconel 600 | min. | 72.0 | – | – | – | – | 14.0 | 6.0 |

| max. | – | 0.5 | 0.15 | 0.015 | 2.0 | 17.0 | 10.0 | |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Hardness (Brinell) |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % | – |

Inconel Weld Neck Flanges are widely utilized in critical and harsh service conditions where both high temperature and chemical resistance are essential. Typical applications include heat exchangers, chemical reactors, superheaters, nuclear power plants, aerospace engine components, marine exhaust systems, and offshore oil and gas platforms. Their sturdy design and extended hub make them ideal for high-pressure pipelines and cyclic loading scenarios. These flanges are especially prized in industries dealing with acidic, oxidizing, and other aggressive environments, ensuring reliability and performance under the toughest conditions.

Yes, we offer custom sizes for Inconel weldneck flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved