Harsh Flanges, located in Mumbai, India, stands out as a leading manufacturer and supplier of high-performance Hastelloy C22 Flanges, designed to provide exceptional corrosion resistance even in the toughest chemical environments. Crafted from a top-quality nickel-chromium-molybdenum-tungsten alloy (Hastelloy C22), these flanges deliver outstanding protection against pitting, crevice corrosion, and stress corrosion cracking. Our Hastelloy C22 flanges meet international standards like ASTM B564 and ASME specifications, ensuring they are precise, strong, and reliable. Harsh Flanges supplies these flanges to vital industries such as chemical processing, pharmaceuticals, marine, and pollution control, where durability and corrosion resistance are absolutely essential.

Hastelloy C22 Flanges are made up of about 56% Nickel, 20–22.5% Chromium, 12.5–14.5% Molybdenum, 2.5–3.5% Iron, and 2.5–3.5% Tungsten, along with trace elements that enhance their performance. These flanges provide remarkable corrosion resistance in both oxidizing and reducing environments. They boast tensile strengths around 690 MPa, yield strength close to 283 MPa, and impressive ductility with elongation reaching up to 45%. Hastelloy C22 flanges maintain their integrity even under high temperatures and chemical exposure, making them perfect for extreme service conditions where standard alloys might fail.

| C22 Forged Fittings Specifications | ASTM B564/ ASME SB564 |

|---|---|

| Alloy C22 Forged Fittings size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Hastelloy C22 Forged Fittings Dimensions | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Hastelloy C22 Forged Fittings Types | Socketweld Fittings, Screwed-Threaded Fittings |

| ASTM B564 C22 Hastelloy Forged Fittings Pressure Rating | Threaded End-2000lb/ 3000lb/ 6000lbs Socket-weld End-3000/ 6000/ 9000lbs |

| Hastelloy C22 Forged Fittings Thread | NPT, BSPT, BSPP |

| C22 Hastelloy Forged Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Nickel Alloy C22 Forged Fittings Origin & Mills | India |

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, and Unions, Forged Pipe Fittings, Socket Weld & Threaded, Equal Tees & Reducing Tees, 90° & 45° Elbows, Plugs |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

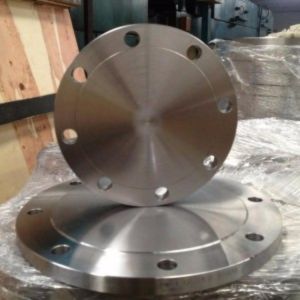

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Hastelloy C22 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Hastelloy C22 Flanges are made up of about 56% Nickel, 20–22.5% Chromium, 12.5–14.5% Molybdenum, 2.5–3.5% Iron, and 2.5–3.5% Tungsten, along with trace elements that enhance their performance. These flanges provide remarkable corrosion resistance in both oxidizing and reducing environments. They boast tensile strengths around 690 MPa, yield strength close to 283 MPa, and impressive ductility with elongation reaching up to 45%. Hastelloy C22 flanges maintain their integrity even under high temperatures and chemical exposure, making them perfect for extreme service conditions where standard alloys might fail.

| ASTM B564 / B564M | Forged Fittings and valves and parts for high temperature service. Standard Specification for Wrought Austenitic Hastelloy Forged Fittings |

| BS21 | Threading. |

| BS3799 | Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry |

| ANSI B16.11 | Forged steel fittings socket-welding and threaded. Socket Welding and Threaded Forged Fittings |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| ISO 4144 | Hastelloy fittings threaded to ISO 7-1. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

Yes, we offer custom sizes for Hastelloy C22 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Hastelloy C22 | N06022 | 2.4602 | – | NiCr21Mo14W | NW 6022 | – | – |

| Grade | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V | Ni |

| C22 | 0.010 | 12.5 – 14.5 | 0.50 | 0.08 | 2.00 – 6.00 | 0.02 | 0.02 | 2.5 | 20 – 22.5 | 2.5 – 3.5 | 0.35 | Bal |

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 45000 , MPa – 310 | Psi – 1,00,000 , MPa – 690 | 45 % |

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved