Harsh Flanges, based in Mumbai, India, stands out as a leading manufacturer and supplier of GOST 33259 Flanges, serving a variety of industrial sectors that adhere to Russian and CIS engineering standards. Our flanges are crafted with precision and are fully compliant with the GOST 33259-2015 standard, which outlines different types of steel pipeline flanges for pressure applications. Renowned for their exceptional build quality, precise dimensions, and resistance to corrosion, our GOST 33259 flanges are trusted across the oil & gas, chemical, and power generation industries. We provide a wide selection in various pressure classes (PN 6 to PN 250), sizes, and material grades.

Our GOST 33259 Flanges are made from top-quality materials like carbon steel (20, 09G2S), stainless steel (12X18H10T), and alloy steel (15X5M, 10X17H13M2T). These materials deliver impressive mechanical strength, boasting tensile strengths of up to 520 MPa and excellent weldability. Designed to thrive in tough environments, these flanges can handle high pressures (PN 6 to PN 250) and a broad temperature range. They also exhibit outstanding resistance to corrosion, oxidation, and wear, making them perfect for both above-ground and buried pipeline systems.

| Standard | GOST / ГОСТ 33259 |

| Size | 1/2″ to 48″ |

| UNI | 6Bar 16Bar 10Bar 25Bar 40Bar |

| Class | 300 LBS, 150 LBS, 900 LBS, 600 LBS, 1500 LBS, 2500 LBS |

| EN | 6Bar 25Bar 10Bar 40Bar 16Bar |

| Flanges Face Type Provided By Manufacturer | RF (Raised Face), RTJ (Ring Type Joint) |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Value Added Services | CNC Machining, Customised Flanges |

| Outer diameters | 1/2” to 24” |

| Making Methods Provided By Manufacturer | Casting And Forging Rolling And Cutting |

| JIS | 5K, 16 K 10 K, 20 K, 40 K, 30 K, 63 K |

| Flanges Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |

| Coating/Surface Treatment By Manufacturer | Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Flanges Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

| Standards Provided By Manufacturer | BS4504, BS 10, API7S-15, JISB2220, BS1560-3.1, ANSI/ASME B16.5/16.36/16.47A/16.47B, EN1092, DIN, API7S-43, API605, B16.48, ISO70051, MSS S44 |

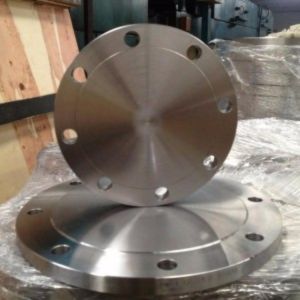

Harsh Flanges a leading supplier in Mumbai, India, offers an extensive selection of GOST 12821-80 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

GOST 33259 Flanges find extensive use in industries that follow Russian standards for pipeline components. They are essential in oil and gas transportation, petrochemical processing, thermal and nuclear power plants, and water treatment facilities. Their sturdy construction and ability to create secure, pressure-tight seals make them ideal for high-pressure steam lines, hazardous fluid systems, and critical infrastructure. Commonly utilized in CIS countries and in international projects that require compatibility with Russian equipment, these flanges come in welded neck, slip-on, blind, and threaded types. Their durability and versatility make them a top choice for both new installations and upgrades.

| Diameter conditional (DN), millimeter | O.D. Of (D), millimeter | Diameter of spacing (D0), millimeter | Diameter internal (dB), millimeter | Flange wall thickness (b), millimeter | fastener Size (d0), millimeter | mounting holes Number (n), pcs | Weight of one flange, kilogram |

| 15 | 80/95 | 55/65 | nineteen | 10/10 | 11/14 | 4/4 | 0.3 / 0.5 |

| 20 | 90/105 | 65/76 | nineteen | 12/12 | 11/14 | 4/4 | 0.5 / 0.7 |

| 25 | 100/115 | 75/85 | nineteen | 12/12 | 11/14 | 4/4 | 0.6 / 0.9 |

| 32 | 120/135 | 90/100 | 39 | 13/14 | 14/18 | 4/4 | 1.1 / 1.4 |

| 40 | 130/145 | 100/110 | 46 | 13/15 | 14/18 | 4/4 | 1.2 / 2 |

| 50 | 140/160 | 110/125 | 59 | 13/15 | 14/18 | 4/4 | 1.3 / 2.1 |

| 65 | 160/180 | 130/145 | 78 | 13/17 | 14/18 | 4/4 | 1.6 / 2.8 |

| 80 | 180/195 | 150/160 | 91 | 15/17 | 18/18 | 4/4 | 2.4 / 3.2 |

| 100 | 205/215 | 170/180 | 110 | 15/19 | 18/18 | 4/8 | 2.8 / 4 |

| 125 | 235/245 | 200/210 | 135 | 17/21 | 18/18 | 8/8 | 3.8 / 5.4 |

| 150 | 260/280 | 225/240 | 161 | 17/21 | 18/22 | 8/8 | 4.4 / 6.6 |

| 200 | 315/335 | 280/295 | 222 | 19/21 | 18/22 | 8/8 | 5.9 / 8 |

| 250 | 370/390 | 335/350 | 273 | 20/23 | 18/22 | 12/12 | 7.6 / 10 |

| 300 | 435/440 | 395/400 | 325 | 20/24 | 22/22 | 12/12 | 10.2 / 13 |

| 350 | 485/500 | 445/460 | 377 | 22/24 | 22/22 | 12/16 | 12.6 / 16 |

| 400 | 535/565 | 495/515 | 426 | 24/26 | 22/26 | 16/16 | 15.2 / 21 |

| 500 | 640/670 | 600/620 | 530 | 25/28 | 22/26 | 16/20 | 19/28 |

| 600 | 755/780 | 705/725 | 630 | 25/31 | 26/30 | 20/20 | 26/40 |

| 800 | 975/1010 | 920/950 | 820 | 27/37 | 30/33 | 24/24 | 46/79 |

| 1000 | 1175/1220 | 1120/1160 | 1020 | 31/43 | 30/33 | 28/28 | 64/118 |

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved