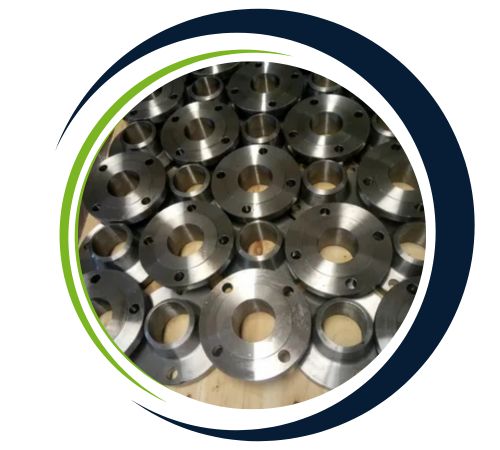

DIN 2543 PN16 Slip On Flanges made to European DIN standards are the speciality of Harsh Flanges, a respectable manufacturer and supplier with headquarters in Mumbai, India. These flanges are frequently used in piping systems for safe and leak-proof connections because they are made for moderate pressure applications. PN16 slip-on flanges are made from premium materials like carbon steel and stainless steel, which guarantee long-lasting performance, corrosion resistance, and precise dimensions. Customers in sectors like chemical processing, oil and gas, and water supply choose Harsh Flanges because we provide products that meet international quality standards.

Stainless steel (SS304/316) or carbon steel (ASTM A105) are the two most common materials used to make DIN 2543 PN16 Slip On Flanges. Carbon, manganese, silicon, chromium, nickel, and molybdenum (in stainless grades) are among their constituent elements. These flanges have an elongation of 20–30%, a yield strength of 250–350 MPa, and a tensile strength of 450–600 MPa. They are perfect for medium-pressure piping systems because they are rated for a nominal pressure of 16 bar (PN16). The choice of material guarantees durability, weldability, and resistance to corrosion in both ambient and slightly higher temperature conditions.

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of DIN 2543 PN16 Slip On Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

| Size Chart | 1/2″ (15 NB) To 48″ (1200NB) |

| Coating Flanges Faces | Zinc Plated, Oil Black Paint, Yellow Transparent, Cold and Hot Dip Galvanized, Anti-rust Paint |

| Design For Size | DIN, EN, ASA, PN, JIS, BS, ANSI, ASME |

| Pressure Rating Table | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Supporting Flanges Material | Flanges Bolts, Gasket, Ring Joint |

| Connect Type Type | FF, RTJ, SMF, LMF, RF, LJF |

| Production Process | Forged, Heat Treated and Machined |

| Standard | ASME B16.38 Flange, DIN Flange, ISO Flange, JIS Flange, PN Flange, MSS SP44 Flange, EN-1092 Flange, BS10 Flange, ASME B16.47 (Series A, Series B) Flange, UNI Flange, ASME B16.5 Flange, AWWA Flange, DIN Flange, GOST Flange |

| Machining Equipment | Bending machine, Sand-blasting machine, Press machine, Pushing Machine, Electric bevelling machine etc |

|

Rated |

d1 |

D |

b |

k |

h1 |

d3 |

s |

r |

h2 |

d4 |

f |

Holes |

Thread |

d2 |

Kg |

|

|

Diameter |

ISO Series |

DIN Series |

||||||||||||||

|

15 |

– |

20 |

95 |

14 |

65 |

35 |

30 |

2 |

4 |

6 |

45 |

2 |

4 |

M 12 |

14 |

0,648 |

|

21,3 |

– |

32 |

||||||||||||||

|

20 |

– |

25 |

105 |

16 |

75 |

38 |

38 |

2,3 |

4 |

6 |

58 |

2 |

4 |

M 12 |

14 |

0,952 |

|

26,9 |

– |

40 |

||||||||||||||

|

25 |

– |

30 |

115 |

16 |

85 |

38 |

42 |

2,6 |

4 |

6 |

68 |

2 |

4 |

M 12 |

14 |

1,14 |

|

33,7 |

– |

45 |

||||||||||||||

|

32 |

– |

38 |

140 |

16 |

100 |

40 |

52 |

2,6 |

6 |

6 |

78 |

2 |

4 |

M 16 |

18 |

1,69 |

|

42,4 |

– |

56 |

||||||||||||||

|

40 |

– |

44,5 |

150 |

16 |

110 |

42 |

60 |

2,6 |

6 |

7 |

88 |

3 |

4 |

M 16 |

18 |

1,86 |

|

48,3 |

– |

64 |

||||||||||||||

|

50 |

– |

57 |

165 |

18 |

125 |

45 |

72 |

2,9 |

6 |

8 |

102 |

3 |

4 |

M 16 |

18 |

2,53 |

|

60,3 |

– |

75 |

||||||||||||||

|

65 |

76,1 |

– |

185 |

18 |

145 |

45 |

90 |

2,9 |

6 |

10 |

122 |

3 |

4 |

M 16 |

18 |

3,06 |

|

80 |

88,9 |

– |

200 |

20 |

160 |

50 |

105 |

3,2 |

8 |

10 |

138 |

3 |

8 |

M 16 |

18 |

3,7 |

|

100 |

– |

108 |

220 |

20 |

180 |

52 |

125 |

3,6 |

8 |

12 |

158 |

3 |

8 |

M 16 |

18 |

4,62 |

|

114,3 |

– |

131 |

||||||||||||||

|

125 |

– |

133 |

250 |

22 |

210 |

55 |

150 |

4 |

8 |

12 |

188 |

3 |

8 |

M 16 |

18 |

6,3 |

|

139,7 |

– |

156 |

||||||||||||||

|

150 |

– |

159 |

285 |

22 |

240 |

55 |

175 |

4,5 |

10 |

12 |

212 |

3 |

8 |

M 20 |

22 |

7,75 |

|

168,3 |

– |

184 |

||||||||||||||

|

200 |

219,1 |

– |

340 |

24 |

295 |

62 |

235 |

5,9 |

10 |

16 |

268 |

3 |

8 |

M 20 |

22 |

11,3 |

|

250 |

– |

267 |

395 |

26 |

350 |

68 |

285 |

6,3 |

12 |

16 |

320 |

3 |

12 |

M 20 |

22 |

14,7 |

|

273 |

– |

292 |

||||||||||||||

|

300 |

323,9 |

– |

445 |

26 |

400 |

68 |

344 |

7,1 |

12 |

16 |

370 |

4 |

12 |

M 20 |

22 |

17,4 |

|

350 |

355,6 |

– |

505 |

26 |

460 |

68 |

385 |

7,1 |

12 |

16 |

430 |

4 |

16 |

M 20 |

22 |

23,6 |

|

– |

368 |

21,6 |

||||||||||||||

|

400 |

406,4 |

– |

565 |

26 |

515 |

72 |

440 |

7,1 |

12 |

16 |

482 |

4 |

16 |

M 24 |

26 |

28,6 |

|

– |

419 |

26,2 |

||||||||||||||

|

(450) |

457 |

– |

615 |

28 |

565 |

72 |

488 |

7,1 |

12 |

16 |

532 |

4 |

20 |

M 24 |

26 |

31,5 |

|

500 |

508 |

– |

670 |

28 |

620 |

75 |

542 |

7,1 |

12 |

16 |

585 |

4 |

20 |

M 24 |

26 |

38,1 |

|

600 |

610 |

– |

780 |

28 |

725 |

80 |

642 |

7,1 |

12 |

18 |

685 |

5 |

20 |

M 27 |

30 |

44,6 |

|

700 |

711 |

– |

895 |

30 |

840 |

80 |

745 |

8 |

12 |

18 |

800 |

5 |

24 |

M 27 |

30 |

62,4 |

|

800 |

813 |

– |

1015 |

32 |

950 |

90 |

850 |

8 |

12 |

18 |

905 |

5 |

24 |

M 30 |

33 |

84,1 |

|

900 |

914 |

– |

1115 |

34 |

1050 |

95 |

950 |

10 |

12 |

20 |

1005 |

5 |

28 |

M 30 |

33 |

98,5 |

|

1000 |

1016 |

– |

1230 |

34 |

1160 |

95 |

1052 |

10 |

16 |

20 |

1110 |

5 |

28 |

M 33 |

36 |

115 |

Water treatment facilities, HVAC systems, chemical processing pipelines, firefighting networks, and low to medium-pressure oil and gas installations are among the many applications for DIN 2543 PN16 Slip On Flanges. These flanges are appropriate for systems that need regular inspection, maintenance, or replacement because of their simple installation and alignment designs. A leak-proof seal is produced by their flat-faced design, which enables uniform gasket compression. PN16 slip-on flanges are trusted in mechanical systems functioning under moderate pressure conditions, industrial plants, and municipal infrastructure because of their sturdy construction and adherence to DIN standards.

Yes, we offer custom sizes for DIN 2543 PN16 Slip On Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved