Harsh Flanges stands out as a top-notch manufacturer and supplier of Carbon Steel F80 Flanges right in the heart of Mumbai, India. With a focus on high-strength carbon steel flanges, this company ensures that all their products meet the ASTM A694 F80 specifications, which guarantees reliability and durability even in the toughest conditions. These flanges are built to handle high-pressure situations, making them perfect for a variety of industrial applications. Harsh Flanges offers a wide selection of flange types, including slip-on, weld neck, blind, and threaded options, all tailored to meet the diverse needs of their clients. With a strong commitment to quality and customer satisfaction, Harsh Flanges has become a trusted partner for industries looking for sturdy flange solutions.

Carbon Steel F80 Flanges, which adhere to ASTM A694 F80 standards, are mainly made up of carbon, manganese, silicon, phosphorus, sulfur, and small amounts of other elements. The carbon content usually falls between 0.26% and 0.60%, giving these flanges their impressive strength and hardness. In terms of mechanical properties, they boast a minimum tensile strength of 550 MPa (80 ksi) and a yield strength of 380 MPa (55 ksi). They also offer excellent weldability and impact resistance, making them reliable even in low-temperature settings. These characteristics make them ideal for high-pressure and critical applications across various industries.

| Standards | ANSI/ASME B16.5, EN Flanges, BS 10, B16.47 Series A & B, EN-1092, ASME Flanges, BS Flanges, B16.48, DIN, DIN Flanges, GOST Flanges, ANSI Flanges, BS4504. |

| Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Production technique | Forged, Heat treated and machined |

| Special design | As per your drawing |

| AS, ANSI, BS, DIN and JIS | |

| 15 NB (1/2″) to 200 NB (8″) | |

| Equal and Reducing Configurations | |

| Connect Type/ Flange Face Type | Ring Type Joint (RTJ), Small Tongue, Raised Face (RF), Lap-Joint Face (LJF), Small Male-Female (SMF), Flat Face (FF), Large Tongue & Groove, Large Male-Female (LMF). |

| Largest Bore Diameter Sizes | NPS ≤ 10 |

| Minimum & Maximum Size | 1/2″ To 48″ |

| Origin | Indian / Japan / Korean / West Europe / USA |

| JIS Standard | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| A182 Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Test Certificates | EN 10204/3.1B |

| Raw Materials Certificate | |

| 100% Radiography Test Report | |

| Third Party Inspection Report, etc. | |

| Application | Gas, Power, Chemical, Metallurgy, Petroleum, Shipbuilding, Construction etc. |

|

Grade |

P |

S |

Mo |

Ni |

Cr |

C |

Si |

Mn |

Cu |

V |

|

A694 |

0.035 |

0.040 |

0.12 |

0.40 |

0.30 |

0.35 |

0.10–0.35 |

0.60–1.05 |

0.40 |

0.08 |

| Grade | Tensile Strength, Min (MPa) | Yield Strength, Min (MPa ) | Elongation, min, % |

|---|---|---|---|

| A694 | 485 | 250 | 30 |

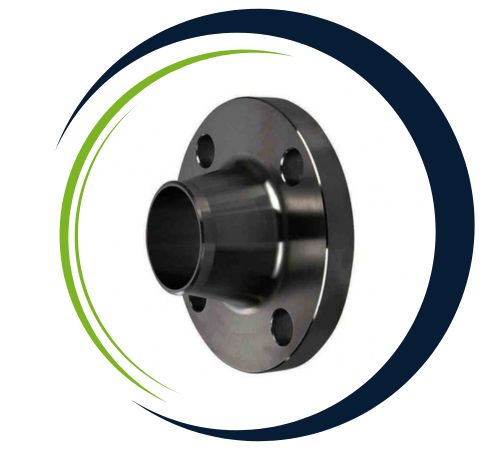

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Carbon Steel F80 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Carbon Steel F80 Flanges are extensively utilized in industries that demand high-strength components capable of enduring elevated pressures. In the oil and gas sector, you’ll find them in pipeline systems and offshore platforms. The petrochemical industry relies on them for refineries and chemical processing units. Power generation plants use these flanges in their steam and water systems. Moreover, they play a vital role in shipbuilding, construction, and heavy engineering projects.

Yes, we offer custom sizes for Carbon Steel F80 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved