Harsh Flanges, located in Mumbai, India, stands out as a top manufacturer and supplier of Carbon Steel F65 Flanges, specifically designed for high-strength and high-pressure applications. Crafted from premium materials, these F65 flanges deliver outstanding mechanical strength and durability, making them perfect for extreme conditions. They are produced in line with industry standards like ASTM A694, ensuring dependable performance in sectors such as oil & gas, petrochemicals, and power generation. Harsh Flanges provides a variety of F65 flanges in different types and sizes, catering to diverse customer needs while guaranteeing exceptional quality, precision, and timely delivery worldwide.

Carbon Steel F65 Flanges are constructed from low-alloy, high-strength carbon steel, enhanced with elements like manganese, chromium, and molybdenum. These flanges boast impressive tensile strength (around 655 MPa) and yield strength (at least 450 MPa), along with remarkable toughness and impact resistance. Built for critical pressure systems, F65 flanges maintain their structural integrity even under high-pressure, high-temperature conditions. Their specific chemical makeup and heat treatment processes enhance their mechanical properties and weldability, making them perfect for demanding pipeline and processing environments.

| Specification Chart Of : | ASTM A694 F65 Flanges |

|---|---|

| ASTM/ ASME Standard Materials | Cast Iron, Inconel, Mild Steel, Stainless Steel, Alloy Steel, Carbon Steel, Duplex Steel & Super Duplex Steel, Hastelloy, Copper Nickel, Wrought Iron. |

| Thickness Calculation AS Per ASME | NPS ≤ 18 |

| Length Chart | (1/2″) To (48″) |

| Manufacturing Process For Flanges |

|

| High Temperature Chart | Above 200° Celsius (400°F) For 150 Class Or Above 400° Celsius (750°F) |

| JIS Standards Manufacturer | 5K, 10K, 40K, 16K 20K 30K, 63K |

| Minimum Size Of Bore Diameter | NPS ≤ 10 |

| Dimensions | ASME B16.36, DIN, AWWA C207, B16.47 Series A & B, BS1560-3.1, EN-1092, ASME B16.48, API605, BS4504, EN1092, UNI, ISO, MSS S44, IS 2062, ISO70051, API, API7S-43, ANSI/ASME B16.5, API7S-15 |

| Pressure Test | 150 LB To 2500 LB |

| Different Face Type | Groove And Small Tongue Groove, RTJ, Flat Face, Lap-Joint Face, Raised Face, Large Tongue & Large Male-Female And Small Male-Female |

| Accept All Small And Large Order Of Type | Blind, Threaded, Lap Joint, Slip-On, Socket-Weld, Weld Neck |

| Application Use In Various Industry | Power Plants Industry Food Processing And Manufacturing Waterworks Systems Nuclear Power Application Municipal Pipe Systems Fossil Fuel Power Plants Oil And Gas Industry |

| Flange Making Format | Forged/ Plate/ Threaded |

| Grade | C | Mn | P | S | Si |

| ASTM A694 F65 Flanges | 0.26-0.265 | 1.60-1.64 | 0.025-0.030 | 0.025-0.030 | 0.15-0.35 |

| Element Of A694 | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| ASTM A694 F65 Flanges | 415 | 450 | 20 % |

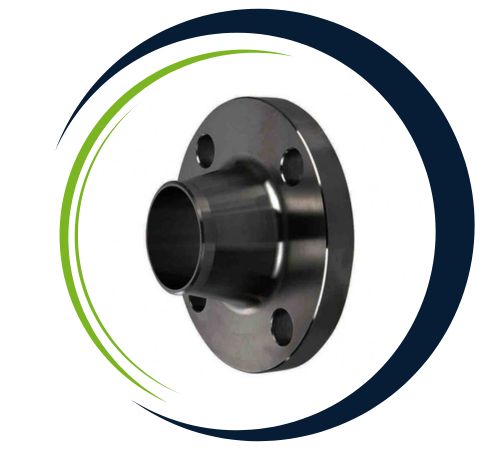

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Carbon Steel F65 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Carbon Steel F65 Flanges find extensive use in high-pressure oil and gas transmission systems, especially in natural gas and petroleum pipeline projects. They’re commonly utilized in fittings for compressors, valves, manifolds, and separators where strength and stress resistance are crucial. These flanges are also essential in offshore platforms, refineries, petrochemical plants, and power generation facilities. Their ability to endure high pressure, corrosion, and mechanical stress makes them vital for critical service applications that require long-term reliability and safety in challenging and dynamic environments.

Yes, we offer custom sizes for Carbon Steel F65 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved