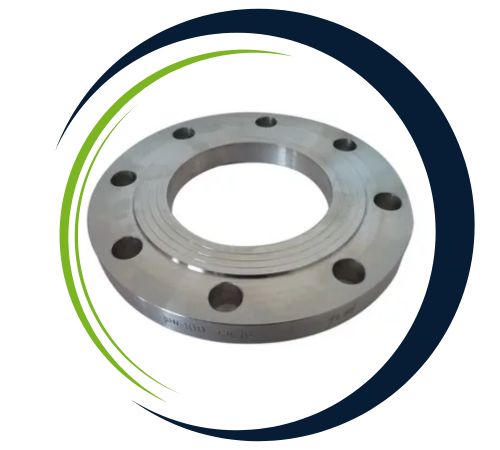

Harsh Flanges, based in Mumbai, India, stands out as a top manufacturer and supplier of API 6A Flanges, specifically crafted for the oil and gas industry’s wellhead and Christmas tree equipment. These flanges are built to meet the rigorous standards of the API 6A specification, ensuring high integrity and safety in critical pressure-containing applications. Renowned for their durability, precise dimensions, and ability to withstand extreme pressure and temperature, Harsh Flanges offers a diverse selection of sizes and pressure classes. We proudly serve global clients involved in upstream oil and gas exploration, production, and drilling operations, delivering premium quality flanges with dependable service.

API 6A Flanges are typically forged from high-quality carbon steel, alloy steel, or stainless steel, including materials like ASTM A105, A182 F11, and F304. These materials provide exceptional tensile strength, often surpassing 620 MPa, along with impressive yield strength and impact resistance. The flanges undergo meticulous heat treatment processes to boost toughness and durability under extreme pressures and temperatures. Designed to resist corrosion, fatigue, and mechanical stress, API 6A flanges maintain their structural integrity in challenging oilfield conditions, ensuring leak-proof connections that are vital for safe wellhead operations.

| Material Specification Of : | (American Petroleum Institute) API Flanges |

|---|---|

| Pressure Rating | Class 150 To Class 2500 |

| High Temperature | Above 200°C (400°F) For Class 150 Or Above 400°C (750°F) |

| Low Temperature | Above -29 Degree C (−20°F) |

| Common Types Of Flanges: | Slip On (SORF), Weld Neck (WNRF), Blind (BLRF), Lap Joint (Loose), Threaded (NPT), Socket-Weld (SWRF) |

| Special Types Of Flanges : | Nipoflange, Elboflange, Latroflange, Swivel Flange, Expanding Flange, Reducing Flange, Weldoflange |

| Standard Cover : | pressure ratings & temperature ratings, materials, marking, dimensions, weight, tolerances, testing |

| Contact Faces | RTJ (Ring Type Joint), FF (Flat Face), RF (Raised Face), T/G (Tongue And Groove ), M/F (Male And Female) |

| Size Chart | Normal Pipe Size 1/2 to NPS 24″ |

| Materials | Stainless Steel (Grade 304/L, 316/L), Carbon Steel (ASTM A105 And ASTM A350), Alloy Steel (ASTM A182), Mild Steel, Duplex Steel, Pressure Vessel Steel, Titanium, Super Duplex Steel, Nickel Alloy, Monel, Inconel, Hastelloy, Copper Nickel, Cast Iron, Wrought Iron. |

| Thickness | Normal Pipe Size ≤ 18 |

| Bore Diameter | Normal Pipe ≤ 10 |

| Flanges Standards | EN 1092-1, JIS, ASME B16.5, ASME B16.47 type A, UNI, DIN |

| Marking Standard | Name of Manufacturer Schedule Type of Flange Facing Nominal Pipe Size Pressure Class ASME B16 Designation |

| Bolt Type | high strength bolts medium strength bolts low strength bolts |

| Gaskets Types | Full Face Gasket Flat Ring Gasket Metallic Ring Gakset |

| Advantages Of Pipe Flange | Used to Connect Pipe System Easy Repair Pipe System Assembled Without Welding |

| Test Pressure | 3 000 PSI | 4 500 PSI | 7 500 PSI | 15 000 PSI | 22 500 PSI | 30 000 PSI |

|---|---|---|---|---|---|---|

| Maximum Pressure (Working) | 2,000 PSI | 3,000 PSI | 5,000 PSI | 10,000 PSI | 15,000 PSI | 20,000 PSI |

| Temperature Rating | K (-60 Deg C) TO Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) | K (-60 Deg C) To Y (+345 Deg C) |

| Product Specification Levels | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 | 1, 2, 3 & 4 |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of API 6a Flange, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

API 6A Flanges play a crucial role in oil and gas wellhead assemblies, Christmas trees, blowout preventers, and pressure control equipment. Their sturdy design enables them to endure the extremely high pressures and harsh conditions faced during drilling and production. These flanges connect valves, pipes, and other essential components, ensuring the safe containment of hydrocarbons and preventing leaks. Commonly found in offshore platforms, onshore drilling rigs, and pipeline systems within upstream oil and gas operations, their reliability and adherence to API standards make them essential for maintaining operational safety.

Yes, we offer custom sizes for API 6a Flange to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

| Weld Neck, Integral, Blinds, Equivalent | |||

| Maximam Working Pressure | 2000 PSI | 3000 PSI | 5000 PSI |

| Test Pressure | PSI 3000 | PSI 4500 | PSI 7500 |

| Product Spec Levels | 1, 2, 3 and 4 | 1, 2, 3 and 4 | 1, 2, 3 and 4 |

| API Temperature Rating | K (-60 ° C) to Y (+345 ° C) | K (-60 ° C) to Y (+345 ° C) | K (-60 ° C) to Y (+345 ° C) |

| Integral, BLRF, Target BLRF and Test Flanges | |||

| Minimam Yield | 60 000 PSI | 60 000 PSI | 60 000 PSI |

| Minimam Tensile | 85 000 PSI | 85 000 PSI | 85 000 PSI |

| Material | API 60K | API 60K | API 60K |

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved