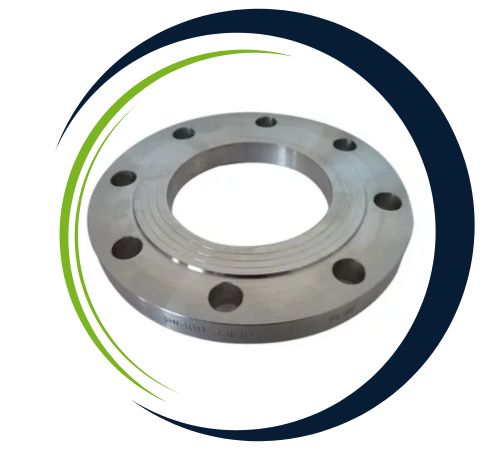

Harsh Flanges, located in Mumbai, India, is a reputable manufacturer and supplier of API 17D Flanges, specifically crafted for subsea equipment in the oil and gas sector. These flanges are produced in line with API 17D standards, ensuring dependable sealing and structural integrity for subsea wellhead and control systems. Renowned for their precision, strength, and resistance to corrosion, Harsh Flanges provides a diverse selection of API 17D flanges in various sizes and pressure ratings. Our products are tailored for offshore exploration, drilling, and production activities, meeting the rigorous demands of subsea environments with exceptional quality and prompt delivery.

API 17D Flanges are generally constructed from high-strength carbon steel and alloy steel grades, including ASTM A105, A182 F22, and various stainless steel options. These materials deliver outstanding tensile strength, often surpassing 620 MPa, along with high yield strength and corrosion resistance, particularly in subsea conditions. The flanges undergo rigorous heat treatment processes to boost toughness and fatigue resistance, which are essential for maintaining pressure in subsea environments. Their strong mechanical properties ensure they can withstand the harsh conditions of underwater settings, pressure changes, and mechanical stresses, making them perfect for subsea wellhead and control system applications.

| Material Specification Of: | API 17D SS Flange |

|---|---|

| API 17d Standard Cover : | pressure ratings & temperature ratings, materials, marking, dimensions, weight, tolerances, testing |

| Contact Faces For API 17d | RTJ (Ring Type Joint), FF (Flat Face), RF (Raised Face), T/G (Tongue And Groove ), M/F (Male And Female) |

| Thickness Of API 17d | Normal Pipe Size ≤ 18 |

| Size Chart | Normal Pipe Size 1/2 to NPS 24 inch |

| Materials | Stainless Steel (Grade 304/L, 316/L), Carbon Steel (ASTM A105 And ASTM A350), Alloy Steel (ASTM A182), Mild Steel, Duplex Steel, Pressure Vessel Steel, Titanium, Super Duplex Steel, Nickel Alloy, Monel, Inconel, Hastelloy, Copper Nickel, Cast Iron, Wrought Iron. |

| Low Temperature Of API 17d | Above -29 Degree C (−20°F) |

| Bore Diameter Of ANSI B16.5 | Normal Pipe ≤ 10 |

| Flanges Standards | EN 1092-1, JIS, ASME B16.5, ASME B16.47 type A, UNI, DIN |

| API 17d Pressure Rating | Class 150 To Class 2500 |

| High Temperature Of API 17d | Above 200°C (400°F) For Class 150 Or Above 400°C (750°F) |

| API 17d Marking Standard | Name of Manufacturer Schedule Type of Flange Facing Nominal Pipe Size Pressure Class ASME B16 Designation |

| API 17d Bolt Type | high strength bolts medium strength bolts low strength bolts |

| European Standard Flanges | JIS B2220 Flanges (5k to 30k) and KS1503 flanges |

| Russian-Standard Flanges | GOST 12820 / 12821-80, DIN, UNI, EN 1092-1 |

| South African Standard Flanges | SANSflanges And SABS flanges |

| Surface Finish Of API 17d | smooth, concentric serrated, stock |

| Advantages Of Pipe Flange | Used to Connect Pipe System Easy Repair Pipe System Assembled Without Welding |

| Flange Face Type | Small Male-Female, Lap-Joint Face, Raised Face, Ring Type Joint, Flat Face, Small Tongue, Large Male-Female, Large Tongue & Groove Flanges manufacturer and Supplier |

| Flanges Marking | All Flanges are marked as follows: Supplier or Manufacturer’s Name, Size, Class, Bore, Dimension, Material, Heat No. Or according to the customer’s request. |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of API 17D Flange, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

API 17D Flanges are mainly utilized in subsea wellhead assemblies, control modules, and valve connections during offshore oil and gas exploration and production. They offer secure, leak-proof sealing solutions for equipment that faces extreme underwater pressures, corrosive seawater, and temperature fluctuations. These flanges play a crucial role in subsea trees, manifolds, and riser systems, ensuring the safe and efficient management of hydrocarbons. Their adherence to API 17D standards guarantees compatibility and reliability in subsea installations, making them essential components in offshore drilling rigs and subsea production systems.

Yes, we offer custom sizes for API 17D Flange to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved