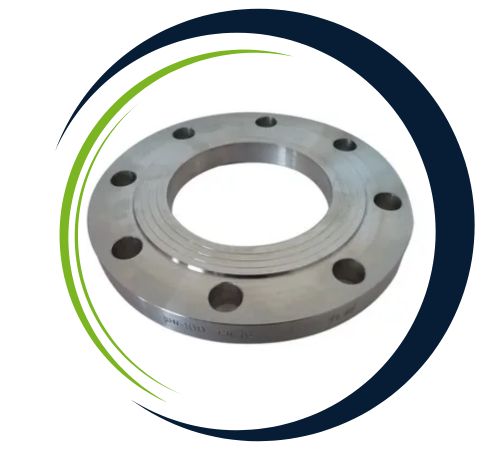

Based in Mumbai, India, Harsh Flanges is a top producer and supplier of alloy steel F9 flanges. With years of experience in the field, we provide high-quality flanges that are renowned for their durability and precise engineering. Using premium raw materials, our Alloy Steel F9 Flanges are made to both national and international standards. With products in a range of sizes, dimensions, and specifications, we serve a variety of industries, such as petrochemicals, power plants, refineries, and oil and gas. Harsh Flanges is a reputable partner for industrial flange solutions globally because of our dedication to customer satisfaction, which includes timely delivery, competitive pricing, and stringent quality checks.

Chromium (8–10%) and molybdenum (0.90–1.10%) make up the majority of alloy steel F9 flanges, along with carbon, manganese, silicon, phosphorus, sulphur, and iron. This composition offers improved toughness, corrosion resistance, and exceptional high-temperature strength. Tensile strength ranges from 415 to 585 MPa, yield strength is at least 205 MPa, and elongation is 20%, among other mechanical characteristics. Under heat stress, the flanges show outstanding mechanical stability and good hardness. These characteristics make alloy steel F9 flanges perfect for uses requiring high strength, resistance to pressure, and performance in challenging and hot conditions.

| Specifications | : | ASTM A182 / ASME SA182 |

| Size | : | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards | : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F9 | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 380 | 585 | 20 % |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Alloy Steel F9 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Industries that require high strength, temperature resistance, and durability frequently use alloy steel F9 flanges. They are frequently used in refineries, petrochemical industries, chemical processing facilities, oil and gas pipelines, and power generation plants. These flanges are perfect for nuclear power systems, boiler systems, heat exchangers, and high-pressure steam lines. They are appropriate for use in offshore, marine, and aerospace platforms due to their strong mechanical characteristics. Additionally, Alloy Steel F9 Flanges are used in mechanical and structural systems where dependable performance in high-temperature and corrosive environments is essential for operational effectiveness and safety.

Yes, we offer custom sizes for Alloy Steel F9 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved