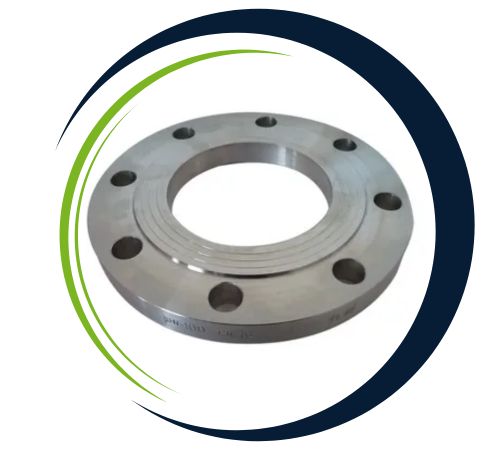

Based in Mumbai, India, Harsh Flanges is a well-known producer and supplier of premium alloy steel F12 flanges. Harsh Flanges provides precisely engineered flange solutions that are suited to satisfy international standards thanks to years of experience and a dedication to quality. Our alloy steel F12 flanges are renowned for their exceptional resistance to high temperatures, high mechanical strength, and dependable operation in mildly corrosive conditions. We are pleased to provide our services to the oil and gas, petrochemical, power generation, and chemical processing industries. Harsh Flanges is a reliable partner for customers worldwide because we promise excellent craftsmanship, affordable prices, and timely delivery.

Chromium (1–1.5%), molybdenum (0.44–0.65%), carbon (0.05–0.15%), manganese, silicon, phosphorus, sulphur, and iron make up alloy steel F12 flanges. Strength, hardness, and heat resistance are all balanced in this composition. Mechanically, F12 flanges have a tensile strength of 485–620 MPa, a yield strength of 275–380 MPa, and an elongation of roughly 20–30%. They function dependably in high-temperature and moderate-pressure environments, guaranteeing durability and structural integrity in crucial applications. Their typical hardness range is 143–197 HB.

| Specifications | : | ASTM A182 / ASME SA182 |

| Size | : | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards | : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F12 | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 275 | 485 | 20 % |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Alloy Steel F12 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Many industries that need components that are durable, high-temperature, and moderately pressurised use alloy steel F12 flanges. They are essential to refinery equipment, wellhead systems, and pipelines in the oil and gas industry. They are essential for steam systems, heat exchangers, boilers, and superheaters in power plants. They are used in reactors, columns, and process piping in the petrochemical and chemical processing industries. They are also used in shipbuilding and marine applications. Where strength, temperature stability, and long-term performance are essential to operational safety and efficiency, their exceptional mechanical qualities and moderate resistance to corrosion make them perfect.

Yes, we offer custom sizes for Alloy Steel F12 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved