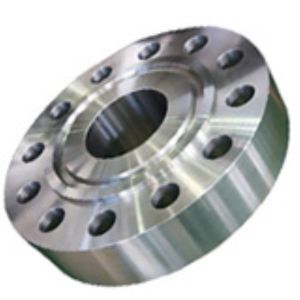

Based in Mumbai, India, Harsh Flanges is a well-known producer and supplier of Alloy 20 RTJ (Ring Type Joint) Flanges. Our speciality is high-performance flanges made for vital industrial applications that demand tight connections and superior corrosion resistance. Alloy 20 RTJ Flanges are designed to withstand harsh chemical conditions, especially those that involve corrosion caused by sulphuric acid and chloride. Our flanges are precisely machined for dependable, high-pressure sealing and meet international standards. Harsh Flanges caters to a wide range of international customers in the chemical, petrochemical, and pharmaceutical sectors with cutting-edge facilities, stringent quality control, and a customer-focused philosophy.

Iron serves as the foundation for Alloy 20 RTJ Flanges, which are made up of 32–38% nickel, 19–21% chromium, 3–4% copper, 2–3% molybdenum, and trace amounts of carbon, manganese, and silicon. Excellent resistance against sulphuric acid and chloride stress corrosion cracking is provided by this special composition. Alloy 20 has a mechanical tensile strength of roughly 551 MPa (80 ksi), yield strength of about 241 MPa (35 ksi), and elongation of roughly 30%. Because of these characteristics and their exceptional metallurgical stability, Alloy 20 RTJ Flanges are perfect for corrosive, high-pressure service environments.

| Specification | ASTM B462 / ASME SB462 |

|---|---|

| Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Ring Type Joint (RTJ), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, Alloy 20-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 ASTM B462 F316 Alloy 20 Flanges |

| Grades | Alloy 20 |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of Alloy 20 RTJ Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

High-pressure applications needing a tight, leak-proof seal—particularly in corrosive environments—frequently use Alloy 20 RTJ Flanges. Chemical processing, pharmaceuticals, food and beverage, petrochemicals, and power generation are examples of typical industries. In systems that handle sulphuric acid, chlorides, and other harsh chemicals, they are perfect for joining pipes, valves, and equipment. These flanges can withstand high temperatures and pressures because of the Ring Type Joint design, which guarantees a tight metal-to-metal seal. They are also useful in heat exchanger, offshore, and marine systems where long-term dependability is crucial due to their exceptional mechanical strength and resistance to corrosion.

| STANDARD | WERKSTOFF NR. | UNS | AFNOR | EN |

| Alloy 20 | 2.4660 | N08020 | Z2NCUD31-20AZ | NiCr20CuMo |

| ASME/ANSI B 16.5 | RTJ Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | RTJ Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | RTJ Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Hubbed Slip-On |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Hubbed Slip-On Hubbed Threaded |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Plate Slip-On Flange, Slip-On Boss Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Yes, we offer custom sizes for Alloy 20 RTJ Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved