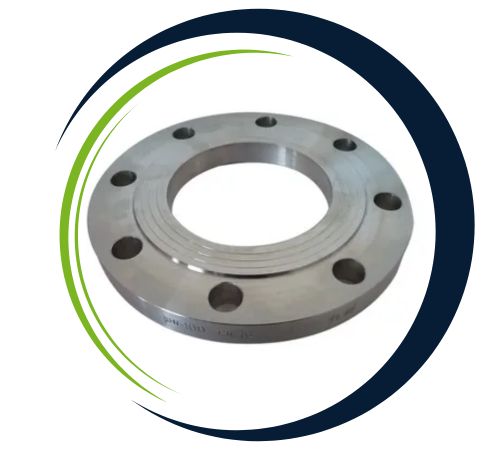

A well-known producer and supplier of high-performance AISI 4130 Flanges for demanding applications in a range of industries, Harsh Flanges is situated in Mumbai, India. The AISI 4130 low-alloy steel used to make these flanges is renowned for its exceptional strength, toughness, and weldability. Our flanges meet international standards and are appropriate for use in critical systems because they are designed to withstand high temperatures and pressures. In order to ensure the highest levels of safety, durability, and performance in demanding working conditions, Harsh Flanges is dedicated to providing dependable, precisely machined flange solutions to industries including oil and gas, petrochemicals, aerospace, and power generation.

About 0.28–0.33% carbon, 0.40–0.60% manganese, 0.80–1.10% chromium, and 0.15–0.25% molybdenum make up AISI 4130 Flanges. This low-alloy steel has good ductility and elongation of about 20–25%, as well as outstanding tensile strength (700–950 MPa), yield strength (460–690 MPa), and impact resistance. Because of these mechanical characteristics, AISI 4130 can be used in high-temperature, high-pressure applications. Additionally, the material provides moderate corrosion resistance and good weldability, especially when heat-treated, which improves performance in corrosive and structurally demanding environments.

| Size | : | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards | : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grade | C | Mn | Si | P | S | Fe | Mo | Ni | Cr |

| AISI 4130 | 0.28-0.33 | 0.40-0.60 | 0.15-0.35 | 0.035 max | 0.025 MAX | 97.3-98.22 | 0.15-0.25 | 0.50 max | 0.80-1.10 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.85 g/cm3 | 1432 ℃ | 560 | 460 | 21.50% |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of AISI 4130 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

The oil and gas, petrochemical, aerospace, and power generation sectors all make extensive use of AISI 4130 flanges in high-pressure systems and structural applications. They are perfect for joining pipelines, valves, and pressure vessels in offshore platforms, drilling rigs, refineries, and subsea machinery. Because of their strength and durability, these flanges are also used in structural tubing, high-stress mechanical assemblies, and hydraulic systems. They are appropriate for demanding applications involving high pressures, dynamic loads, and aggressive media due to their resistance to fatigue and stress corrosion. Under both static and cyclic service conditions, AISI 4130 Flanges offer long-term performance and structural integrity.

Yes, we offer custom sizes for AISI 4130 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | EN |

| AISI 4130 | 1.7218 | G41300 | JIS G4105 | BS 970 | 25CrMo4 |

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved