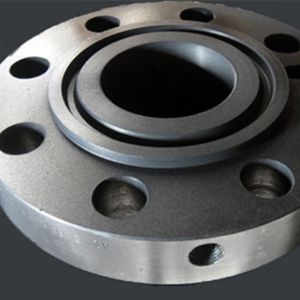

Premium-grade 16Mo3 Flanges made for high-temperature and high-pressure applications are available from Harsh Flanges, a reputable manufacturer and supplier with headquarters in Mumbai, India. Durability and performance in demanding environments are guaranteed by the manufacturing of these flanges in accordance with international standards like EN 10222-2 and EN 10028-2. Boiler, heat exchanger, and pressure vessel applications benefit greatly from 16Mo3 flanges, which are renowned for their exceptional mechanical strength and resistance to heat stress. Harsh Flanges provides dependable flange solutions to industries like power generation, petrochemical, and process engineering from its state-of-the-art production facilities, stringent quality control, and dedication to on-time delivery.

The main constituents of 16Mo3 Flanges are carbon and molybdenum (0.25–0.35%), with trace amounts of silicon, phosphorus, sulphur, and manganese. Excellent oxidation resistance and high-temperature strength are provided by this composition. These flanges have good elongation of about 22%, a yield strength of ≥220 MPa, and a tensile strength of 440–590 MPa. Because of their strong mechanical characteristics, they can be used in high-temperature applications, guaranteeing structural stability, resistance to pressure, and durability in challenging conditions—particularly in situations where fatigue resistance and thermal creep are crucial.

| Specifications | 16Mo3 Flanges |

|---|---|

| Coating | Anti-rust Paint/ Zinc Plated/ Oil Black Paint/ Yellow Transparent/ Cold and Hot Dip Galvanized |

| Manufacturer of | Forged/ Threaded/ Screwed / Plate |

| Manufacturer Length | NPS 1⁄₂” Inch To NPS 48” Inch |

| Face Type | RTJ/ RF/ FF |

| Schedule Chart | SCH 5S To XXS. |

| Vishal Steel Manufacturer Belbow Types | Weld Neck/ Socket Weld/ Threaded/ Reducing/ Lap Joint/ Blind/ Slip On |

| Forging Methods | Forging & Casting, Rolling & Cutting |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Application | Bitumen upgraders Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids. |

| JIS Standard | 5K/ 10K/ 16K 20K/ 30K/ 40K/ 63K |

| Flange Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |

| Supporting Material | Gasket/ Ring Joint/ Flange Bolts |

| Production Technique | Forged/ Heat treated and machined |

| Packing | Plywood Pallet And Plywood Box |

| Brand | Vishal Steel |

| Productivity | 800 ton per month |

| Transportation | Ocean And Air |

| Supply Ability | 700 Ton Per Month |

| Flange Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

Element | Percentage % | Element | Percentage % |

P | 0.025 | V | – |

S | 0.010 | Al | – |

Cr | 0.030 | N | 0.012 |

Mo | 0.25/0.35 | Cu | 0.30 |

C | 0.12/0.20 | Ni | 0.30 |

Si | 0.35 | Nb | – |

Mn | 0.40/0.90 | Ti | – |

| 16Mo3 Flanges | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation in 100-150 mm(%) | Maximum Thickness (mm) | Elongation in 16 mm(%) |

| 440-590 | 220-275 | 19 | 250 | 24 |

DIN,WNr | BS | UNI | ISO | DIN | UNS |

16Mo3 | 240 | 16Mo3 | P26 | 1.5415 | K11562 |

243 | TS26 |

| Grade | Thickness | Temperature (°C) | |||||||||

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | ||

(mm) | MPa | MPa | MPa | MPa | MPa | MPa | MPa | MPa | MPa | MPa | |

| 16Mo3 Flanges | ≤16 | 273 | 264 | 250 | 233 | 213 | 194 | 175 | 159 | 147 | 141 |

>16 ≤40 | 268 | 259 | 245 | 228 | 209 | 190 | 172 | 156 | 145 | 139 | |

>40 ≤60 | 258 | 250 | 236 | 220 | 202 | 183 | 165 | 150 | 139 | 134 | |

>60 ≤100 | 238 | 230 | 218 | 203 | 186 | 169 | 153 | 139 | 129 | 123 | |

>100 ≤150 | 218 | 211 | 200 | 186 | 171 | 155 | 140 | 127 | 118 | 113 | |

>150 ≤250 | 208 | 202 | 191 | 178 | 163 | 148 | 134 | 121 | 113 | 108 | |

Harsh Flanges, a leading supplier in Mumbai, India, offers an extensive selection of 16Mo3 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

In systems with high temperatures and pressures where resistance to corrosion and thermal stress is essential, 16Mo3 flanges are widely used. Boilers, heat exchangers, reactor systems, pressure vessels, and steam pipelines are examples of common applications. They are especially well-suited for waste incineration facilities, power plants, chemical processing facilities, and oil refineries. Under extreme chemical exposure and varying heat loads, the flanges guarantee dependable sealing and long-term durability. Because of their improved material qualities, they are a popular option for joining pipes and equipment in systems that use hot gases, superheated steam, and corrosive fluids at high temperatures.

| Normal Pipe Size | DN |

|---|---|

| 1/2 | 15 |

| 3/4 | 20 |

| 1 | 25 |

| 1 1/4 | 32 |

| 1 1/2 | 40 |

| 2 | 50 |

| 2 1/2 | 65 |

| 3 | 80 |

| 4 | 100 |

| Flanges Size inches | Flanges Size millimeter | Outer Diameter (O.D.) inches | Outer Diameter (O.D.) millimeter | Inner Diameter (I.D.) inches | Inner Diameter (I.D.) millimeter | Ø B.H.C. In inches | Ø B.H.C. In millimeter | Ø B.H. inches | Ø B.H. millimeter | # B.H. | Thickness inches | Thickness millimeter | Weight lbs | Weight Kilogram |

| 8.0 | 200 | 13.39 | 340 | 8.72 | 221.50 | 11.61 | 295 | 0.870 | 22 | 12 | 1.020 | 26 | 21.0 | 9.5 |

| 10.0 | 250 | 15.94 | 405 | 10.88 | 276.40 | 13.97 | 355 | 1.020 | 26 | 12 | 1.140 | 29 | 31.0 | 14.1 |

| 12.0 | 300 | 18.11 | 460 | 12.88 | 327.20 | 16.14 | 410 | 1.020 | 26 | 12 | 1.260 | 32 | 42.7 | 19.4 |

| 14.0 | 350 | 20.47 | 520 | 14.19 | 360.40 | 18.50 | 470 | 1.020 | 26 | 16 | 1.380 | 35 | 62.3 | 28.3 |

| 15.0 | 400 | 22.83 | 580 | 16.19 | 411.20 | 20.67 | 525 | 1.180 | 30 | 16 | 1.500 | 38 | 80.5 | 36.5 |

| 17.0 | 450 | 25.20 | 640 | 18.19 | 462.00 | 23.03 | 585 | 1.180 | 30 | 20 | 1.650 | 42 | 110.3 | 50.1 |

| 19.0 | 500 | 28.15 | 715 | 20.19 | 512.80 | 25.59 | 650 | 1.300 | 33 | 20 | 1.810 | 46 | 141.5 | 64.2 |

| 24.0 | 600 | 33.07 | 840 | 24.19 | 614.40 | 30.32 | 770 | 1.420 | 36 | 20 | 2.050 | 52 | 213.5 | 96.9 |

| Normal Size Of Steel Pipe | Outer Diameter (O.D.) | 10 Schedule | 20 Schedule | 30 Schedule | STD Wall | 40 Schedule | 60 Schedule | EXT Hvy | 80 Schedule | 100 Schedule | 120 Schedule | 140 Schedule | 160 Schedule | XX Hvy |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 0.84 | 0.083 | … | … | 0.109 | 0.109 | … | 0.147 | 0.147 | … | … | … | 0.188 | 0.294 |

| ¾ | 1.05 | 0.083 | … | … | 0.113 | 0.113 | … | 0.154 | 0.154 | … | … | … | 0.219 | 0.308 |

| 1 | 1.315 | 0.109 | … | … | 0.133 | 0.133 | … | 0.179 | 0.179 | … | … | … | 0.25 | 0.358 |

| 1 ¼ | 1.66 | 0.109 | … | … | 0.14 | 0.14 | … | 0.191 | 0.191 | … | … | … | 0.25 | 0.382 |

| 1 ½ | 1.9 | 0.109 | … | … | 0.145 | 0.145 | … | 0.2 | 0.2 | … | … | … | 0.281 | 0.4 |

| 2 | 2.375 | 0.109 | … | … | 0.154 | 0.154 | … | 0.218 | 0.218 | … | … | … | 0.344 | 0.436 |

| 2 ½ | 2.875 | 0.12 | … | … | 0.203 | 0.203 | … | 0.276 | 0.276 | … | … | … | 0.375 | 0.552 |

| 3 | 3.5 | 0.12 | – | – | 0.216 | 0.216 | – | 0.3 | 0.3 | – | – | – | 0.438 | 0.6 |

| 3 ½ | 4 | 0.12 | – | – | 0.226 | 0.226 | – | 0.318 | 0.318 | – | – | – | – | 0.636 |

| 4 | 4.5 | 0.12 | – | – | 0.237 | 0.237 | – | 0.337 | 0.337 | – | 0.438 | – | 0.531 | 0.674 |

| 5 | 5.563 | 0.134 | – | – | 0.258 | 0.258 | – | 0.375 | 0.375 | – | 0.5 | – | 0.625 | 0.75 |

| 6 | 6.625 | 0.134 | – | – | 0.28 | 0.28 | – | 0.432 | 0.432 | – | 0.562 | – | 0.719 | 0.864 |

| 8 | 8.625 | 0.148 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 |

| 10 | 10.75 | 0.165 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.5 | 0.594 | 0.719 | 0.844 | 1 | 1.125 | 1 |

| 12 | 12.75 | 0.18 | 0.25 | 0.33 | 0.375 | 0.406 | 0.562 | 0.5 | 0.688 | 0.844 | 1 | 1.125 | 1.312 | 1 |

| 14 | 14 | 0.25 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.5 | 0.75 | 0.938 | 1.094 | 1.25 | 1.406 | – |

| 16 | 16 | 0.25 | 0.312 | 0.375 | 0.375 | 0.5 | 0.656 | 0.5 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | – |

| 18 | 18 | 0.25 | 0.312 | 0.438 | 0.375 | 0.562 | 0.75 | 0.5 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | – |

| 20 | 20 | 0.25 | 0.375 | 0.5 | 0.375 | 0.594 | 0.812 | 0.5 | 1.031 | 1.281 | 1.5 | 1.75 | 1.969 | – |

| 22 | 22 | 0.25 | – | – | 0.375 | – | – | 0.5 | – | – | – | – | – | – |

| 24 | 24 | 0.25 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.5 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | – |

| 26 | 26 | – | – | – | 0.375 | – | – | 0.5 | – | – | – | – | – | – |

| 30 | 30 | 0.312 | 0.5 | 0.625 | 0.375 | – | – | 0.5 | – | – | – | – | – | – |

Yes, we offer custom sizes for 16Mo3 Flanges to meet specific project needs. Our team at Harsh Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@harshflanges.co.in.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Harsh Flanges, All rights reserved